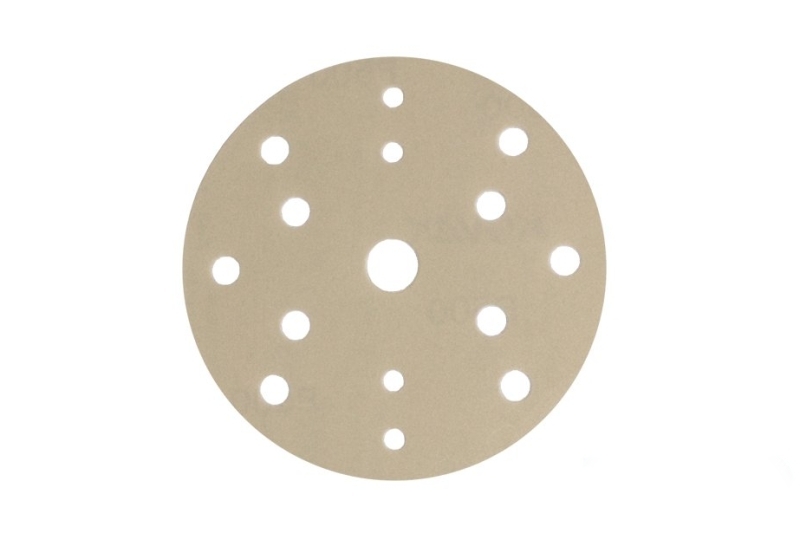

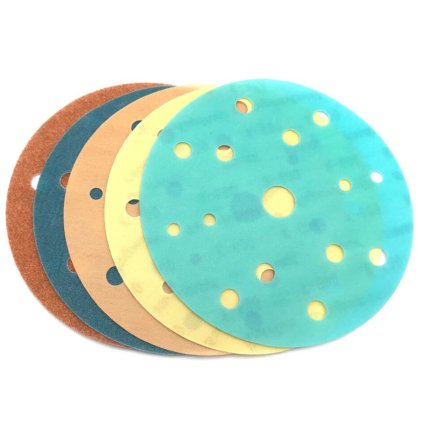

Circular grinding segments

Resin sanding is a relatively straightforward process with circular sanding pads, provided a few principles are followed. Sanding clear casting resin involves progressing gradually from coarse to fine grit (for example, 600 to 3000). How do you sand resin? We start by sanding with a coarser grit to remove any significant unevenness. By switching to a finer grit, we smooth the surface to a perfect finish. Epoxy resins are a common material for making resin jewellery, resin furniture and resin decorations, and in their manufacture it is very often necessary to grind and polish resin surfaces. Epoxy resins are sanded gradually in steps from coarse grit to fine, and the final treatment of the casting resin can be resin polishing, if we want to achieve such an effect. After coarse sanding of the resin (grit P40 to K600), comes finer sanding (grit K600 to K1500), and very fine sanding of the resin is carried out with discs with a grit of K2000 and K3000. For a perfect result, we recommend Kovax circular segments of the highest quality.

Resin sanding is a relatively straightforward process with circular sanding pads, provided a few principles are followed. Sanding clear casting resin involves progressing gradually from coarse to fine grit (for example, 600 to 3000). How do you sand resin? We start by sanding with a coarser grit to remove any significant unevenness. By switching to a finer grit, we smooth the surface to a perfect finish. Epoxy resins are a common material for making resin jewellery, resin furniture and resin decorations, and in their manufacture it is very often necessary to grind and polish resin surfaces. Epoxy resins are sanded gradually in steps from coarse grit to fine, and the final treatment of the casting resin can be resin polishing, if we want to achieve such an effect. After coarse sanding of the resin (grit P40 to K600), comes finer sanding (grit K600 to K1500), and very fine sanding of the resin is carried out with discs with a grit of K2000 and K3000. For a perfect result, we recommend Kovax circular segments of the highest quality.

Product sorting

List of products

Sanding Set for machine sanding of resin surfaces – ideal for eccentric sanders with a 150 mm disc (152 mm discs).