Hand sanding resin

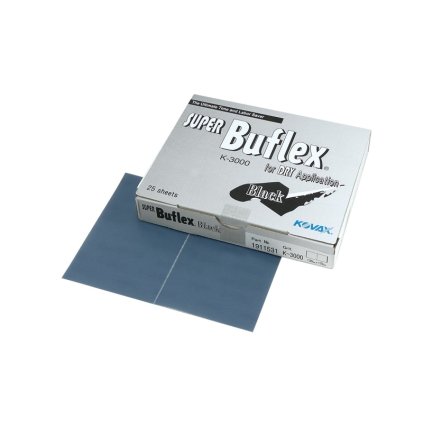

How to sand resin? Resin sanding methods can be divided into manual resin sanding (manual epoxy resin sanding) and machine resin sanding. Manual sanding can be done dry or underwater. For both methods, we use sandpaper for resin sanding. They have a different bond and abrasive grain compared to sandpaper for wood or metal. For dry hand sanding, we have a hand block with hook and loop for easy replacement of sandpaper of various grits. The hand block is ideal for sanding flat surfaces or edges. We don't use a hand block for sanding small resin products; we hold the sandpaper in our hand. For wet sanding, we only need our hands; wet sandpaper does not have hook and loop. The number that indicates sandpaper denotes its grit. A lower number indicates coarse sandpaper, and a higher number indicates fine sandpaper. There are two important principles for sanding epoxy resin. 1. The removed dust between the product and the sandpaper needs to be constantly removed, preferably with a microfibre cloth. This principle does not apply to wet resin sanding; the water washes away the removed material itself. 2. We sand the resin gradually with individual sandpaper grits. To achieve a perfect result, we must not skip any grits. The resin sanding kit contains all the necessary grits for gradual sanding.

How to sand resin? Resin sanding methods can be divided into manual resin sanding (manual epoxy resin sanding) and machine resin sanding. Manual sanding can be done dry or underwater. For both methods, we use sandpaper for resin sanding. They have a different bond and abrasive grain compared to sandpaper for wood or metal. For dry hand sanding, we have a hand block with hook and loop for easy replacement of sandpaper of various grits. The hand block is ideal for sanding flat surfaces or edges. We don't use a hand block for sanding small resin products; we hold the sandpaper in our hand. For wet sanding, we only need our hands; wet sandpaper does not have hook and loop. The number that indicates sandpaper denotes its grit. A lower number indicates coarse sandpaper, and a higher number indicates fine sandpaper. There are two important principles for sanding epoxy resin. 1. The removed dust between the product and the sandpaper needs to be constantly removed, preferably with a microfibre cloth. This principle does not apply to wet resin sanding; the water washes away the removed material itself. 2. We sand the resin gradually with individual sandpaper grits. To achieve a perfect result, we must not skip any grits. The resin sanding kit contains all the necessary grits for gradual sanding.

Product sorting

List of products

Sanding Pad Set – a basic selection for dry resin sanding. Premium sheets ensure even removal and low clogging.

Sanding Pad Set – a basic selection for dry resin sanding. Premium sheets for even abrasion and low clogging, complete with a hand block.

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)