Machine grinding of resin

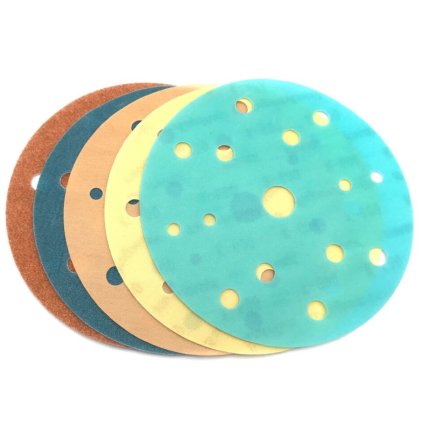

Machine sanding of epoxy resin requires equipment - brusks for epoxy. For sanding epoxy resin in large areas, such as a resin table, resin furniture or resin boards, we will need a larger sander. It can be a vibrating sander or an eccentric sander. Vibrating sanders use a square format of sandpaper and eccentric sanders a circular format. Smaller resin products, especially sanding resin jewellery, will need a hand sander. We most often use it for rough shaping, fine sanding and final polishing of the resin. We always use sandpaper for sanding resin. It has a different bond and abrasive grain compared to sandpaper for wood or metal. The number that indicates the sandpaper indicates its grit. A lower number indicates coarse sandpaper, and a higher number indicates fine sandpaper. We sand the resin with individual sandpaper grits gradually. To achieve a perfect result, we must not skip any grits. The resin sanding kit contains all the necessary grits for gradual sanding. The following applies to sanding epoxy resin Important principle: oThe abraded dust between the product and the sandpaper needs to be constantly removed, preferably with a microfibre cloth. If the sander is equipped with extraction, this worry is eliminated.

Machine sanding of epoxy resin requires equipment - brusks for epoxy. For sanding epoxy resin in large areas, such as a resin table, resin furniture or resin boards, we will need a larger sander. It can be a vibrating sander or an eccentric sander. Vibrating sanders use a square format of sandpaper and eccentric sanders a circular format. Smaller resin products, especially sanding resin jewellery, will need a hand sander. We most often use it for rough shaping, fine sanding and final polishing of the resin. We always use sandpaper for sanding resin. It has a different bond and abrasive grain compared to sandpaper for wood or metal. The number that indicates the sandpaper indicates its grit. A lower number indicates coarse sandpaper, and a higher number indicates fine sandpaper. We sand the resin with individual sandpaper grits gradually. To achieve a perfect result, we must not skip any grits. The resin sanding kit contains all the necessary grits for gradual sanding. The following applies to sanding epoxy resin Important principle: oThe abraded dust between the product and the sandpaper needs to be constantly removed, preferably with a microfibre cloth. If the sander is equipped with extraction, this worry is eliminated.

Product sorting

List of products

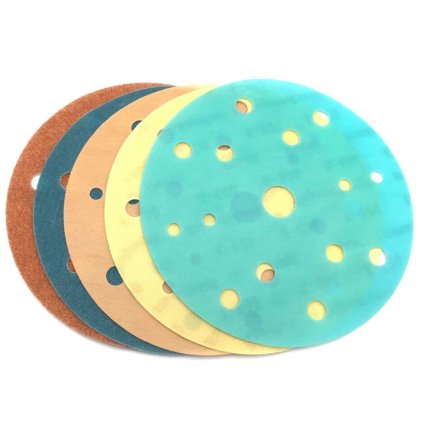

Sanding Set for machine sanding of resin surfaces – ideal for eccentric sanders with a 150 mm disc (152 mm discs).

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)